A bad refrigerator compressor can be identified by unusual noises and a failure to cool the food properly. In addition, the fridge might run continuously or not turn on at all, indicating a faulty compressor.

A compressor is an essential component of a refrigerator that controls the refrigerant flow and maintains the cooling process. When it malfunctions, it can result in inadequate cooling and potential damage to the appliance.

Identifying these signs allows homeowners to address the issue promptly and seek professional assistance for repairs or replacements.

Common Symptoms Of A Bad Refrigerator Compressor

If your refrigerator is not cooling properly or is making strange noises, it could be a sign of a bad compressor. Look out for symptoms like warm temperatures inside the fridge and freezer, frequent cycling on and off, and loud clicking or humming sounds.

Fridge Not Cooling Properly

If your refrigerator is not cooling as efficiently as it used to, it could be a sign of a bad compressor. Look out for the following symptoms:

- Lack of cool air: One of the most apparent signs of a bad compressor is when your fridge fails to maintain a cool temperature. Your food may spoil quicker, and items like ice cream might melt faster than normal.

- Uneven cooling: If certain parts of the refrigerator are colder than others, it could be due to a faulty compressor. You may notice that some food items freeze while others remain at an improper temperature.

Pay attention to these symptoms as they may indicate a problem with your fridge’s compressor.

Noises Coming From The Refrigerator

Unusual noises emanating from your refrigerator could also be an indicator of a faulty compressor. Keep an ear out for the following sounds:

- Clicking noise: If you hear a clicking sound coming from your fridge, particularly when it starts or stops running, it could signal a problem with the compressor relay switch.

- Rattling or vibrating noise: A compressor that is going bad may produce rattling or vibrating sounds. These noises can usually be heard near the back of the refrigerator.

Don’t ignore strange noises from your fridge, as they may be a warning sign of a faulty compressor.

Frequent Temperature Fluctuations

Another common symptom of a bad refrigerator compressor is frequent temperature fluctuations. Look out for the following signs:

- Inconsistent cooling: If the temperature inside your refrigerator frequently rises and falls, it may indicate compressor issues. This fluctuation can lead to partially frozen or spoiled food.

- Frost buildup: Excessive frost or ice accumulation on the walls or food items is another sign of a malfunctioning compressor. This occurs when the compressor fails to maintain the appropriate cooling conditions.

- Take note of any temperature inconsistencies or frost buildup in your refrigerator, as they could indicate a faulty compressor.

By paying attention to these common symptoms, you can identify if your refrigerator compressor is going bad. Addressing the issue promptly will help ensure the longevity and functionality of your appliance.

If you’re experiencing any of these symptoms, it might be wise to consult a professional for diagnosis and repair.

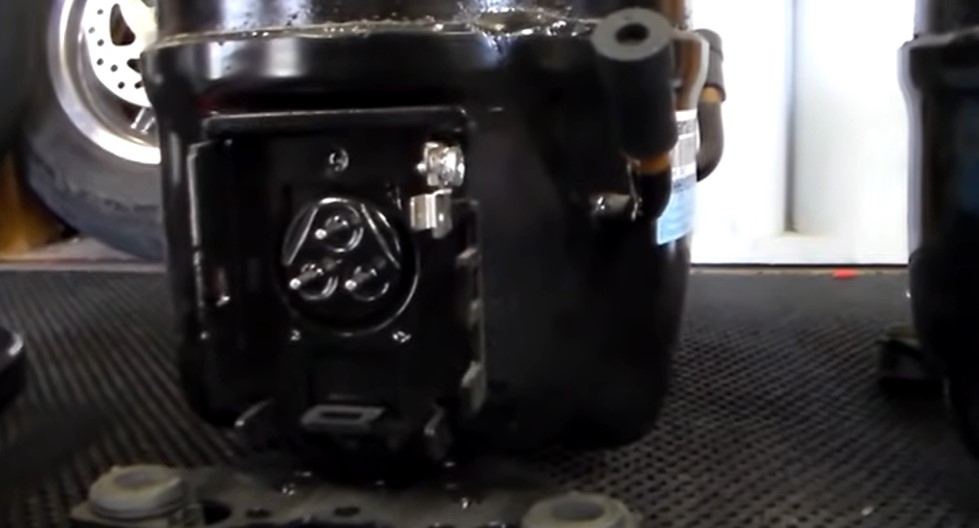

Visual Inspection

One way to determine if a refrigerator compressor is bad is through visual inspection. Look for signs such as oil leaks, unusual noises, or a lack of cooling.

Look For Oil Spots Or Leaks Around The Compressor:

- Inspect the area around the refrigerator compressor for any oil spots or leaks. These can be indicators of a faulty compressor.

- Oil spots or leaks could mean that there is a refrigerant leak, which can lead to improper cooling and other performance issues.

- If you notice any oil spots or leaks, it is recommended to call a professional technician to diagnose and repair the problem.

Check For Damaged Or Frayed Wires:

- Take a close look at the wires connected to the refrigerator compressor. Look for any signs of damage or fraying.

- Damaged or frayed wires can lead to electrical issues, such as a short circuit or power failure.

- Ensure that the wires are properly insulated and securely connected.

- If you notice any damage or fraying, it is advisable to have a qualified technician replace the wires to avoid any safety hazards.

Observe Any Strange Or Burning Odor:

- Pay attention to any unusual odors coming from the refrigerator compressor.

- A strange or burning odor could indicate a problem with the compressor motor or electrical components.

- If you detect any strange smells, it is essential to address the issue promptly by calling a professional to prevent potential hazards or further damage to the refrigerator.

When visually inspecting a refrigerator compressor, it is important to check for oil spots or leaks, examine wires for any damage or fraying, and be mindful of any strange or burning odors. These visual inspections can provide valuable insights into the health of the compressor and help identify if it is experiencing any issues.

If you notice any abnormalities, it is always best to consult a professional technician for proper diagnosis and repair.

Testing The Compressor Motor

Testing the compressor motor is crucial in determining if a refrigerator compressor is bad. By assessing the motor’s functionality, you can identify issues and decide whether a replacement is necessary.

When it comes to determining if a refrigerator compressor is bad, testing the compressor motor is an essential step. By checking for continuity in the motor windings and measuring the resistance of the start and run windings, you can assess the health of the compressor.

Here are the steps you can follow to test the compressor motor using a multimeter and measure the resistance:

Use A Multimeter To Check For Continuity In The Motor Windings:

- Start by unplugging the refrigerator from the power source to ensure your safety.

- Locate the compressor motor terminals, usually found at the back of the refrigerator near the bottom.

- Set your multimeter to the resistance or ohms mode.

- Place one probe on any one of the motor terminals and the other probe on another terminal.

- Note the reading displayed on the multimeter.

- Repeat the process for each combination of the motor terminals.

- If the multimeter shows infinite or open circuit readings in any combination, it suggests a lack of continuity in the motor windings, indicating a bad compressor.

Measure The Resistance Of The Start And Run Windings:

- With the refrigerator still unplugged, identify the start and run windings of the compressor. Refer to the manufacturer’s documentation if needed.

- Set the multimeter to the resistance or ohms mode.

- Touch one probe to the start winding terminal and the other probe to the common terminal.

- Note the resistance reading displayed on the multimeter.

- Repeat the process for the run winding terminal and the common terminal.

- Compare the resistance readings with the manufacturer’s specifications. If the resistance values are significantly different or if they read as open circuits, it indicates a faulty compressor motor.

Remember, if you’re not confident in performing these tests or interpreting the results, it is always recommended to consult a professional technician. They have the expertise to accurately diagnose and fix any issues with your refrigerator compressor.

Checking The Electrical Components

To determine if a refrigerator compressor is malfunctioning, it is important to check the electrical components. This involves examining the wiring, capacitors, and relays for any signs of damage or lack of connectivity. Additionally, testing the compressor with a multimeter can provide insight into its functionality.

Inspect The Start Relay, Overload Protector, And Capacitor

When it comes to diagnosing a bad refrigerator compressor, checking the electrical components is essential. Inspecting the start relay, overload protector, and capacitor can help determine if there are any issues causing the compressor to malfunction.

Here’s what you need to know:

- Start relay: This component is responsible for providing the initial electrical impulse to start the compressor. It’s located at the back of the refrigerator, typically near the compressor. Check for any signs of damage or burnt connectors.

- Overload protector: The overload protector protects the compressor from overheating. It’s often located next to the start relay. Make sure it’s not loose or burnt, as this can indicate a faulty compressor.

- Capacitor: The capacitor stores electrical energy to provide an extra boost when starting the compressor. Inspect the capacitor for any bulging or leaking. A damaged capacitor may prevent the compressor from running efficiently.

Remember, make sure to unplug the refrigerator and discharge any electrical charge before touching any of these components. If you’re unsure or uncomfortable working with electrical parts, it’s best to seek professional assistance.

Ensure The Condenser Fan And Evaporator Fan Are Working Correctly

In addition to checking the electrical components, it’s crucial to ensure the condenser fan and evaporator fan are working correctly. These fans play a vital role in the proper functioning of the refrigerator compressor. Here’s what you need to do:

- Condenser fan: The condenser fan is located near the compressor and helps cool down the refrigerant. Check if the fan is spinning freely and that its blades are clean. If the fan is not running properly, it can lead to compressor issues.

- Evaporator fan: The evaporator fan is situated inside the freezer or refrigerator compartment and circulates the cold air. Open the freezer or refrigerator door and listen for the sound of the fan running. If you don’t hear anything, it could indicate a problem with the fan motor or control board.

If either of the fans is not functioning correctly, it’s recommended to consult a professional technician to diagnose and repair the issue. Faulty fans can put additional strain on the compressor and affect its performance.

Remember, regular maintenance and cleaning of the refrigerator can help prevent compressor problems and extend its lifespan.

Using Gauges For Refrigerant Levels

Refrigerant levels can be assessed using gauges to determine if a refrigerator compressor is bad. By measuring the pressure in the system, the gauges provide valuable insights into the health of the compressor, helping to identify any potential issues before they become major problems.

When it comes to troubleshooting a refrigerator compressor, one important step is to check the refrigerant levels. This is where using gauges comes in handy. By connecting gauges to measure the low and high side pressures, you can get valuable insights into the condition of the refrigerator compressor.

Below, i will explain how to use gauges and compare the readings to the manufacturer’s specifications:

Connect Gauges To Measure Low And High Side Pressures:

- Attach the blue hose to the low-pressure port and the red hose to the high-pressure port on the gauges.

- Make sure the valves on the gauges are closed before connecting them to the refrigerator’s service ports.

- Once the gauges are securely connected, open the valves slowly to allow the pressure to equalize.

- Leave the gauges connected for a few minutes to get accurate readings.

Compare The Readings To The Manufacturer’S Specifications:

- Consult the manufacturer’s manual or documentation for the recommended low and high side pressure ranges.

- Take note of the readings on the gauges for both the low and high side pressures.

- Compare the readings to the manufacturer’s specifications to determine if they are within the acceptable range.

- If the readings are significantly higher or lower than the recommended range, it may indicate a problem with the compressor.

Remember, accurately measuring the low and high side pressures with gauges is crucial in assessing the condition of a refrigerator compressor. If you notice any abnormalities in the readings, it is recommended to seek professional assistance to diagnose and repair the compressor.

Replacing The Compressor

If you’re wondering how to tell if your refrigerator compressor is bad, look out for signs such as warm temperature inside the fridge, unusual noises, or a constantly running motor. Replacing a faulty compressor may be necessary to restore your appliance’s cooling functionality.

If you suspect that your refrigerator compressor is bad and needs to be replaced, here is a step-by-step procedure you can follow:

- Disconnect the power: Before you start working on your refrigerator, make sure to unplug it from the power source. This is crucial for your safety and to avoid any electrical accidents.

- Locate the compressor: The compressor is usually located at the back of the refrigerator, at the bottom. It is a cylindrical or rectangular-shaped device that helps cool the refrigerant.

- Remove the components: To access the compressor, you may need to remove certain components such as the back cover or any other obstructing parts. This can usually be done with basic tools like a screwdriver or socket wrench.

- Release refrigerant: If the old compressor still contains refrigerant, you will need to evacuate it by using a recovery machine or seeking professional help. Refrigerant must be properly disposed of to comply with environmental regulations.

- Detach the compressor: Once the refrigerant is removed, disconnect any electrical connections to the compressor. Depending on the model, you may need to disconnect wires or unscrew terminals. Take note of which wires go where to ensure proper reconnection later.

- Remove mounting bolts: The compressor is usually held in place by mounting bolts or brackets. Use a suitable tool to remove these bolts, carefully keeping track of each bolt and its position.

- Replace the compressor: With the old compressor removed, it’s time to install the new one. Ensure that you purchase the correct compressor model for your refrigerator make and model. Follow the reverse steps of the removal process to install the new compressor, reconnecting wires and mounting bolts.

- Consideration of compressor cost and warranty: When replacing the compressor, it is important to consider the cost of the new part and the warranty it comes with. Choosing a compressor with a longer warranty period can provide you with peace of mind against any future compressor-related issues.

Remember, if you’re not confident in your diy skills or face any difficulties during the process, it’s always advisable to contact a professional technician or service center to avoid further damage to your refrigerator.

By following these steps and considering the cost and warranty of the new compressor, you should be well on your way to successfully replacing a bad refrigerator compressor.

Considering Professional Help

Are you experiencing issues with your refrigerator? Unsure if the compressor is to blame? Consider seeking professional help to accurately diagnose and address the problem.

If you’re dealing with a potentially faulty refrigerator compressor, it’s important to consider seeking professional help. A licensed technician can provide expert diagnosis and repair services for your appliance. Here are some reasons why consulting a professional might be the best option:

- Expert diagnosis: A licensed technician is trained to identify and diagnose issues with refrigerator compressors. They have the necessary knowledge and experience to pinpoint the root cause of the problem accurately. By consulting a professional, you can ensure an accurate assessment of the compressor’s condition.

- Repair expertise: Repairing a refrigerator compressor requires specialized skills and knowledge. A licensed technician has the expertise to tackle compressor repairs effectively. They can perform the necessary repairs, replace faulty parts, and ensure that your compressor is working optimally.

- Safety considerations: Refrigerators contain complex electrical and mechanical components, including the compressor. Attempting to repair or replace a compressor without proper training can be dangerous. A licensed technician will prioritize safety and ensure that all repairs are done according to industry standards.

- Warranty coverage: If your refrigerator is still under warranty, attempting to repair the compressor yourself or through an unqualified technician can void the warranty. By consulting a licensed technician, you can ensure that the repairs are done in a way that maintains the warranty coverage.

- Cost assessment: A professional can help you weigh the cost of repairs against the price of a new refrigerator. They can provide you with an estimate of the repair costs and guide you in making an informed decision. Sometimes, the cost of repairing an old compressor may not be justifiable, and it may be more financially viable to invest in a new appliance.

Seeking professional help for a faulty refrigerator compressor is the best way to ensure accurate diagnosis, proper repairs, and overall safety. It also allows you to make an informed decision by considering the cost of repairs versus buying a new refrigerator.

Remember, the expertise of a licensed technician can save you time, money, and potential headaches in the long run.

Understanding DIY Fixes

When troubleshooting a refrigerator, it’s important to understand diy fixes. If your refrigerator compressor is bad, look out for signs such as constant noise, warm temperatures, or spoiled food to determine if a replacement is needed.

When it comes to a bad refrigerator compressor, there are a few temporary solutions you can try before calling a professional. These fixes may not completely solve the problem, but they can provide some relief until you can get the compressor repaired or replaced.

Here are a couple of diy fixes to consider:

- Adding refrigerant: If your refrigerator is not cooling properly, it could be due to low refrigerant levels. You can purchase a refrigerant recharge kit and follow the instructions to add more refrigerant to the system. However, this is merely a temporary solution, as refrigerant leaks can lead to further compressor damage.

- Cleaning the condenser coils: Over time, dust and debris can accumulate on the condenser coils, making it harder for the compressor to cool the refrigerator. By cleaning the coils regularly, you can improve the efficiency of the compressor. Here’s how to do it:

- Unplug the refrigerator to ensure safety.

- Locate the condenser coils, which are usually found at the back of the fridge or beneath it.

- Use a vacuum cleaner or a brush to remove any dirt or dust from the coils.

- Be gentle to avoid damaging the coils or other components.

- Plug the refrigerator back in and observe if there is any improvement in cooling.

Proper Maintenance Practices To Prevent Compressor Issues

Preventing compressor problems is always ideal. By following proper maintenance practices, you can extend the life of your refrigerator compressor. Here are a few tips to keep in mind:

- Clean the refrigerator regularly: Dust and dirt can find their way into various parts of the refrigerator, including the compressor. Regularly cleaning the interior and exterior surfaces can prevent the build-up of debris, ensuring optimal performance.

- Check the door seals: Damaged or improperly sealed door gaskets can lead to air leaks and energy wastage. Make sure the door seals are intact and clean. If necessary, replace them to maintain a proper seal, allowing the compressor to work efficiently.

- Avoid overloading: Putting excessive items in the refrigerator can strain the compressor and reduce its lifespan. Ensure proper air circulation by not overcrowding the refrigerator, allowing it to cool evenly.

- Maintain proper temperature settings: Set the refrigerator temperature between 37-40°f (3-4°c) and the freezer temperature between 0-5°f (-18 to -15°c) for optimal cooling performance. Extreme temperature settings can overwork the compressor.

- Regularly defrost the freezer: Ice buildup in the freezer can impair the compressor’s cooling function. Keeping your freezer free from excessive ice will help your compressor operate efficiently.

Remember, while these maintenance practices can reduce the risk of compressor issues, it is still important to seek professional help if you suspect a serious problem with your refrigerator compressor.

Frequently Asked Questions Of How Do You Know If A Refrigerator Compressor Is Bad

How Do You Test A Refrigerator Compressor?

To test a refrigerator compressor, follow these steps:

1. Unplug the fridge from the power source and remove the rear panel.

2. Check for any visible damage or leaking oil around the compressor.

3. Use a multimeter to test the compressor’s windings for continuity.

4. Set the multimeter to the ohms setting and touch the meter leads to the compressor’s terminals.

5. If the meter reads a low resistance value (around 3 to 4 ohms), the compressor is functioning properly.

6. If there is no continuity or the reading is significantly higher, the compressor may be faulty and requires replacement.

7. Reassemble the fridge and plug it back in to observe if the compressor is running.

8. If the compressor starts and the fridge cools as usual, it is likely working correctly. Otherwise, seek professional help.

What Does A Refrigerator Sound Like When The Compressor Is Going Out?

A refrigerator with a failing compressor may make unusual sounds. Most common is a loud banging, clicking, buzzing, or humming noise.

What Is The Lifespan Of A Refrigerator Compressor?

The lifespan of a refrigerator compressor typically ranges from 10 to 20 years, depending on several factors. Regular maintenance, such as cleaning the coils and checking the refrigerant levels, can prolong its lifespan. However, environmental conditions, usage patterns, and manufacturing quality can also impact the longevity of the compressor.

Is It Worth Replacing Compressor On Refrigerator?

Yes, replacing the compressor on a refrigerator is usually worth it. The compressor is the heart of the refrigerator’s cooling system, and if it fails, the fridge won’t be able to maintain the required temperature. Buying a new refrigerator can be expensive, so replacing the compressor is a more cost-effective option.

Additionally, if your refrigerator is relatively new or a high-end model, investing in a new compressor can extend its lifespan and save you money in the long run. It’s important to consult a professional technician to determine if the compressor is the root cause of the problem and to assess the overall condition of your appliance.

They can provide guidance on whether it’s worth replacing the compressor or if other factors, such as the age and condition of the refrigerator, should be taken into consideration.

Conclusion

Determining if a refrigerator compressor is bad can be a daunting task, but recognizing the signs is crucial to avoiding further damage. By paying attention to the unusual noises, warm temperatures, and excessive cycling of your refrigerator, you can identify potential compressor issues.

If you notice your fridge is not cooling properly, it’s important to consult a professional for an accurate diagnosis and timely repair. Taking immediate action can save you from expensive repairs or even complete breakdowns in the future. Remember to clean the condenser coils regularly, as this simple maintenance step can help prevent compressor problems.

Additionally, monitoring the energy usage of your refrigerator and being aware of any sudden spikes can also be an early indication of compressor issues. By staying vigilant and addressing problems promptly, you can prolong the lifespan of your refrigerator and keep your food fresh for longer.